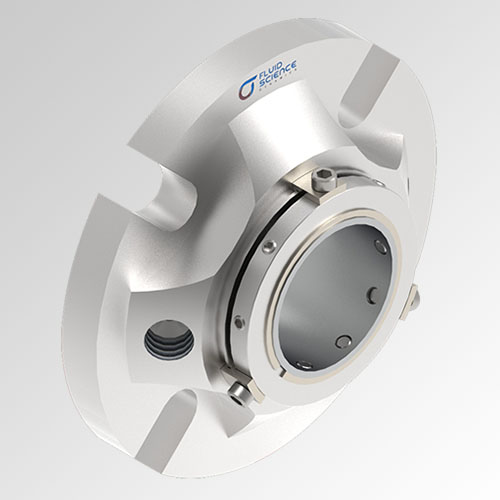

F-SSCS (Single Standard Cartridge Seal)

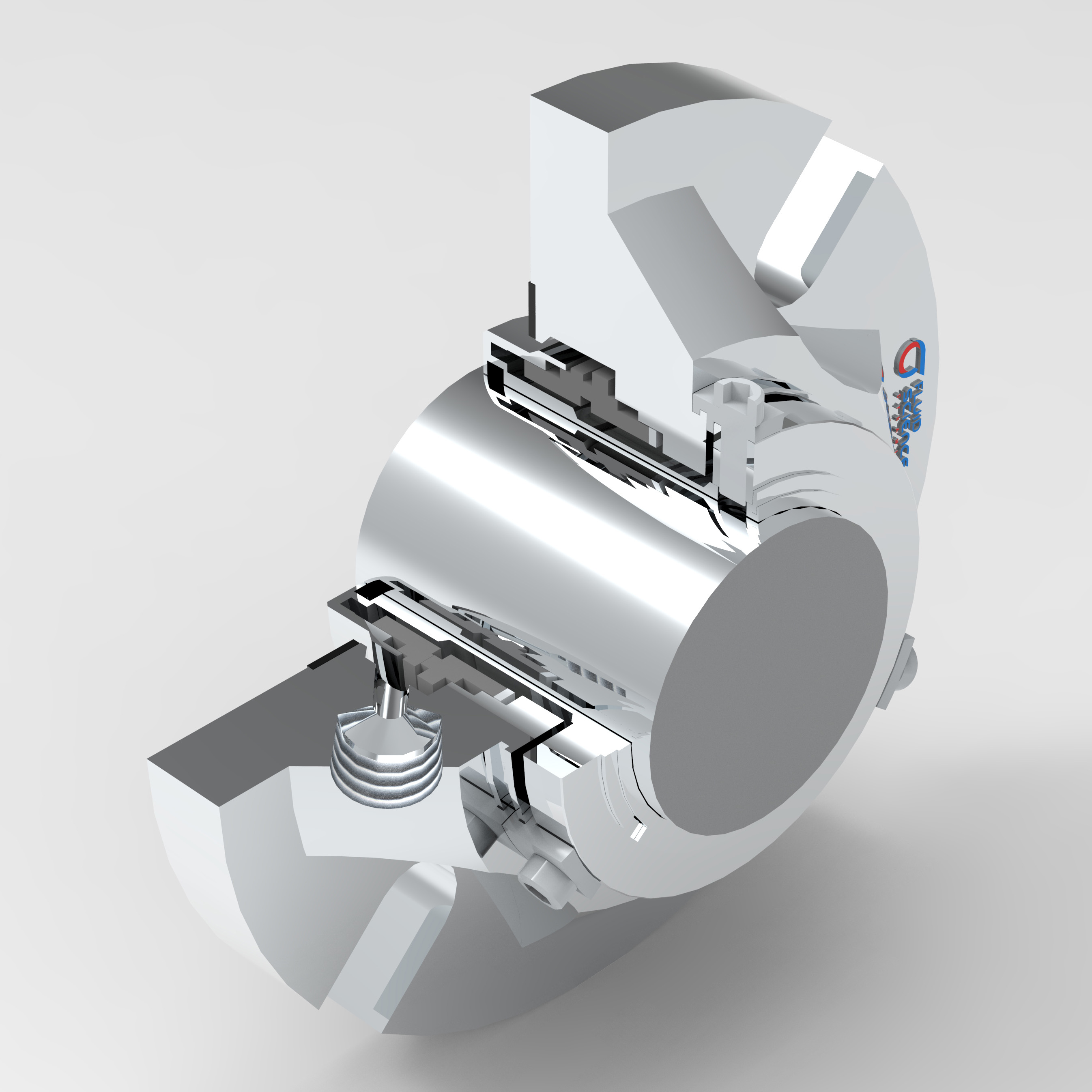

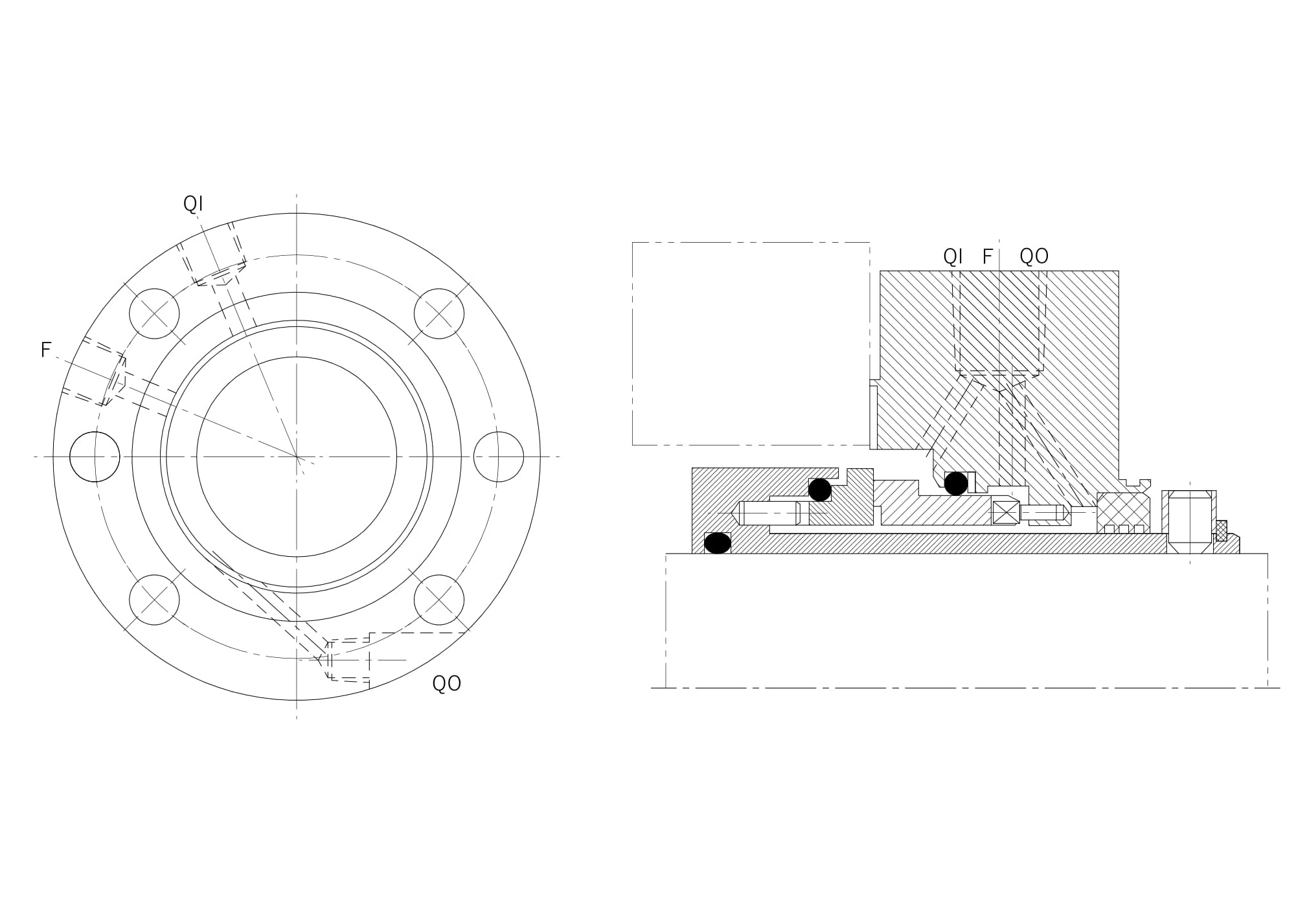

Type F-SSCS is designed to accommodate medium duty applications in various industries, especially difficult and ardous applications found on-site. All seal faces are monolithic construction thereby eliminating distortion in high and low temperature applications. Seal faces are double balanced to ensure excellent sealing at high or low differential pressure, minimize seal face distortion to ensure stable fluid film conditions between seal faces. An alternative design for hot liquid applications, typically for boiler feed and low vapour pressure products, the unique bi-directional pumping ring design coupled with stationary deflector delivers high volumes of barrier fluid to the seals in constant directions.

Design Features :

- Hydraulically balanced seal faces.

- Reliable face drive mechanism with monolithic seal face materials.

- Unique bi-directional pumping ring (for boiler feed and low vapour pressure products).

- Easy-to-install cartridge design with registered fit.

- Available in standard / medium / big bore gland design.

Parameters

Performance :

- Pressure : up to 2.5 MPa

- Temperature : -40°C to 320°C

- Speed : up to 20 m/s

- Size range : 25mm to 125mm (1.0 inch to 5.0 inches)

Materials :

- Rotary face : SiC, TC

- Stationary face : Carbon, SiC, TC

- Spring : Alloy C-276, SS 316L

- O-ring : Sillicon, EPDM, FKM, Aflas, FFKM

Recommended Application

Scopes of Application :

- Industries: Oil & Gas, Petrochemical, Chemical, Power Gen, General Industries.

- Equipment: Process Pump, Mixer, Blower.

Customization :

Changes of materials for other operating parameters are possible. Contact us with your requirements.