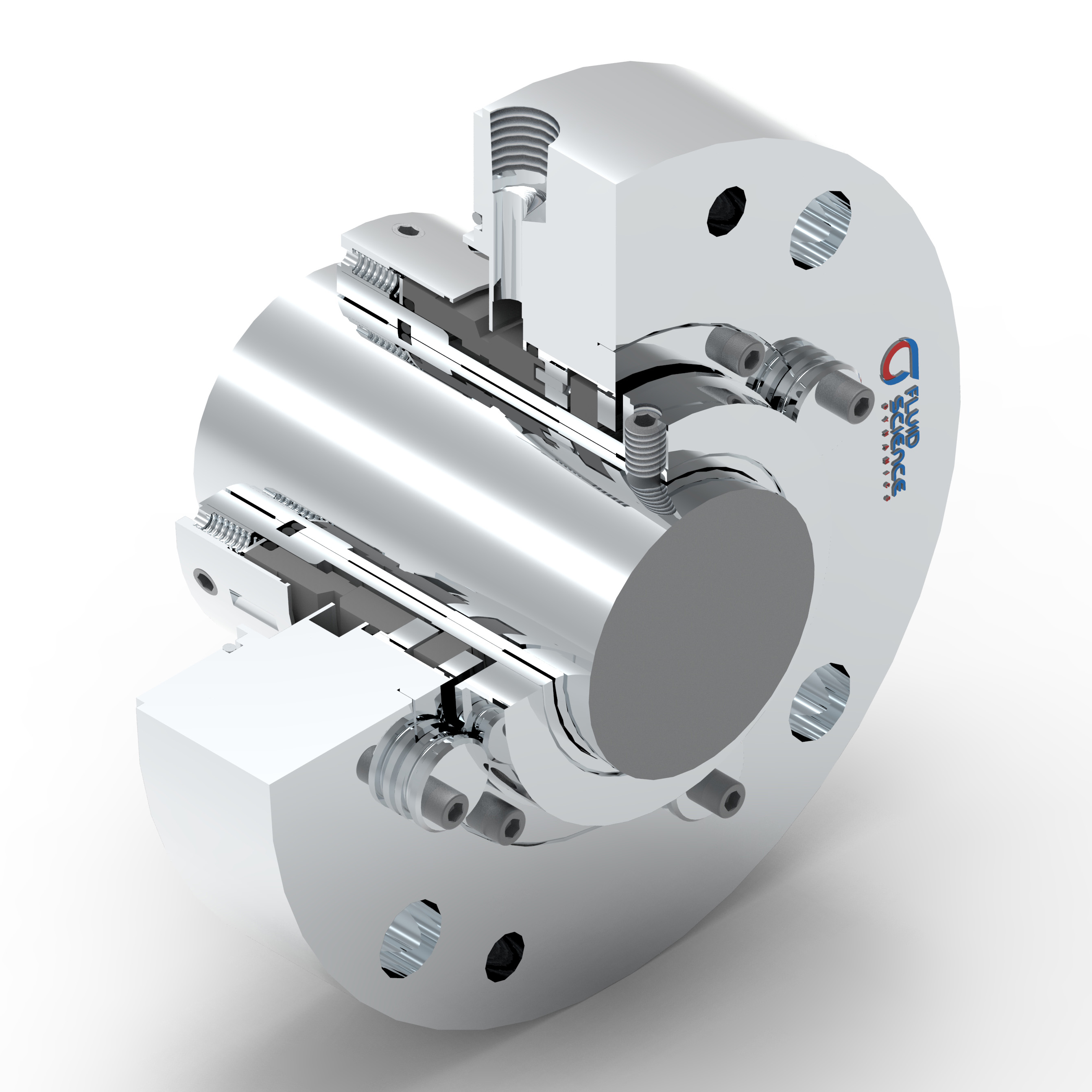

FAP8-1

Type FAP8-1 multiple spring pusher seal (API 682 Categories 2 and 3, Type A, Arrangement 1) is specified within API 682 for sealing low temperature flashing hydrocarbons. Type FAP8-1 seal is designed to minimize the pressure distortion and flashing potential of light hydrocarbon fluids to provide long seal life and low fugitive emissions. Typically, a Plan 11 flush or a Plan 23 is applied depending on the pumping temperature. If the pumping temperature is above 140°F/60°C, acirculating device should be added.

Dual unpressurized (FAP8-2) and dual pressurized (FAP8-3) seals may also be considered for these services, especially LPGs.Type FAP8-1 single seals typically control emissions to less than 500 ppm.

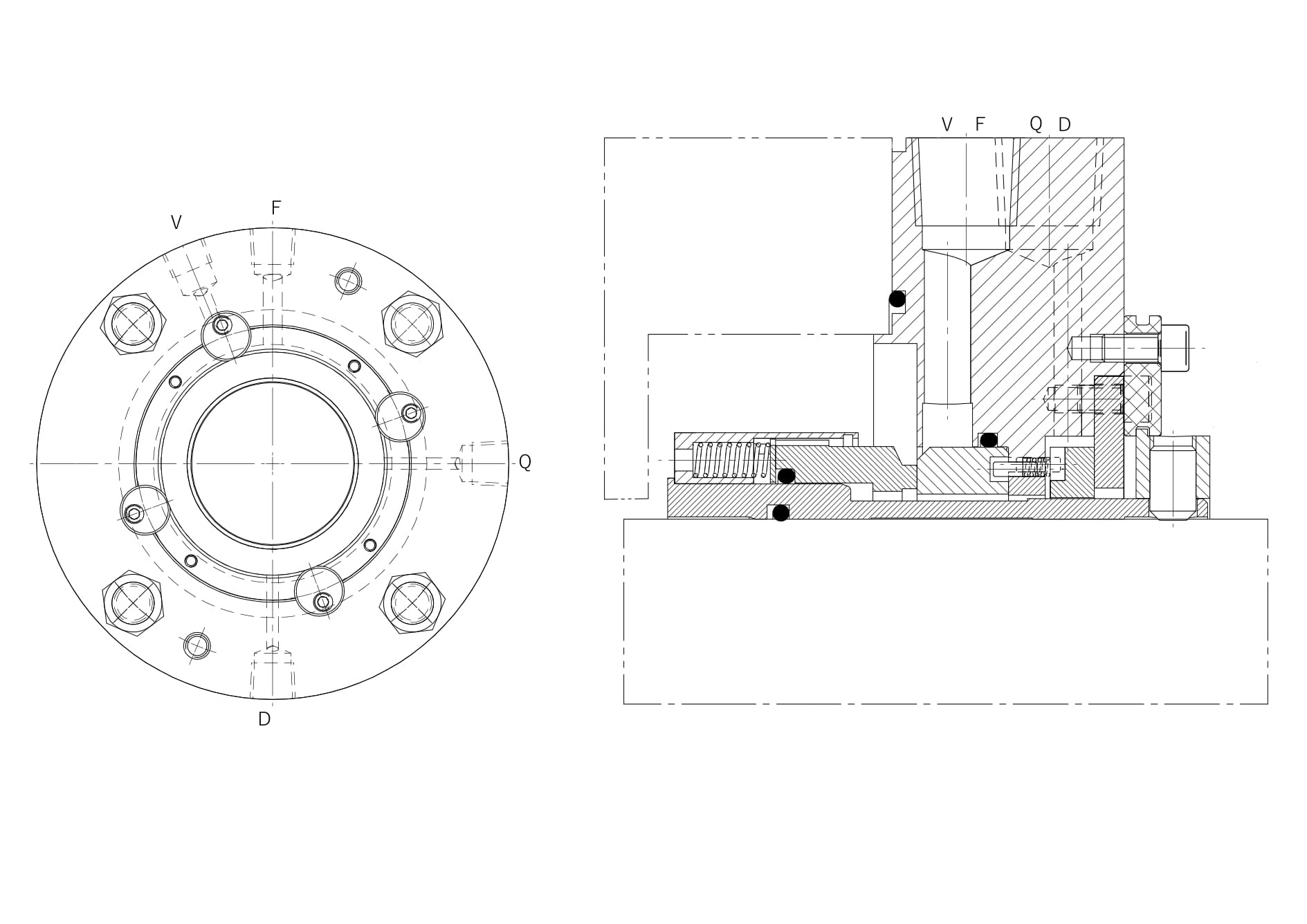

Design Features:

- API 682 qualification tested.

- Easy-to-install cartridge design with registered fit.

- Segmented spring-loaded carbon throttle bushing for effective containment.

- Distributed flush optimizes circulation of liquid at faces and prevents trapped vapor.

- Available with pumping ring when utilizing an API Flush Plan 23.

- Dual seals equipped with pumping ring for optimized flow.

Parameters

Performance:

- Pressure : up to 1000 PSIG

- Temperature : -40°C to 260°C

- Speed : up to 25 m/s

- Size range : 1.000" to 4.500" (25mm to 120mm)

Materials:

- Rotary face : Antimony Carbon, SiC, TC

- Stationary face : SiC, TC

- Spring : Alloy C-276, SS 316L

- O-ring : EPDM, FKM, Aflas, FFKM

Recommended Application

Scopes of Application:

- Fully meets the needs of the oil and gas industry for hydrocarbon and other services as defined by API 682 for Type A seal duties. This includes: heavy and light hydrocarbons, lubricating liquids, aqueous solutions, chemicals, and some acids.

- Industrial applications involved in the processing of VOCs and similar hazardous products.

Customization:

Customization of design is possible to suit youroperating parameters. Please contact us with yourrequirements.