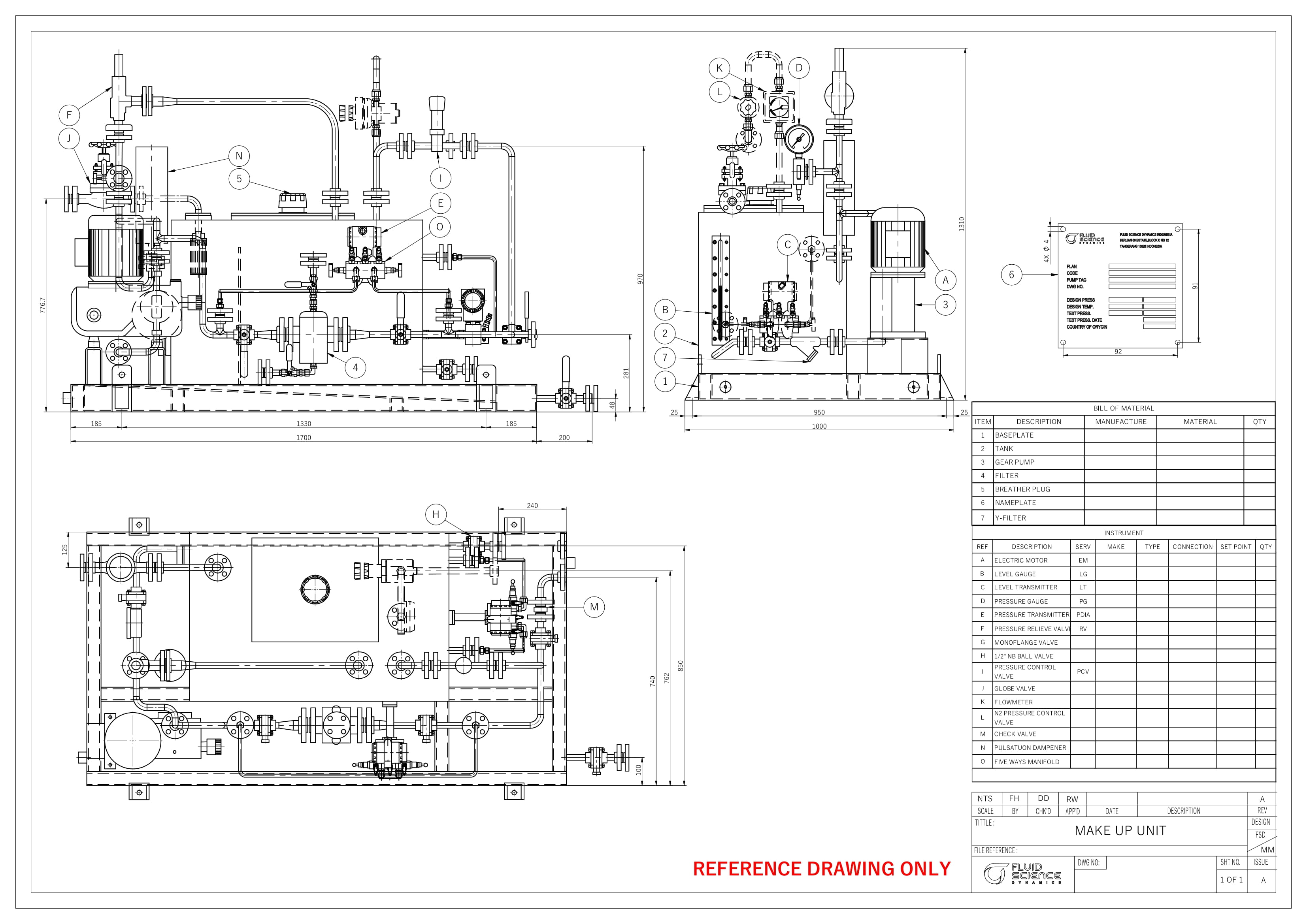

API PLAN 54

Pressurized external barrier fluid system supplying clean liquid for an arrangement 3 pressurized dual seal. The barrier liquid is maintained at a pressure greater than seal chamber pressure and is circulated by an external pump or pressure system.

Features

- Most reliable of all dual pressurized plans when properly engineered.

- Provides barrier liquid circulation and cooling even though the process pump is in stand-by mode.

- The pumped fluid becomes contaminated but never leaks to the atmosphere unless the system pressure is lost.

- Ensures positive barrier fluid circulation and better heat dissipation due to higher flow rates as compared to 53A, 53B or 53C. Heat is removed with the help of a water cooler or an air cooler.

- Uses a pump to ensure barrier liquid circulation and pressurization.

- May employ a nitrogen / inert gas blanket for barrier oil applications.

Recommended Application

Remarks Checkpoints :

- Check with the process engineer if product contamination is acceptable.

- Check barrier fluid compatibility with the media.

- In case the system has a strainer or a filter, check for blockages.

- Note that the loss of pressure in the system may cause the pumped media to enter the entire Plan 54 system.

- Ensure that the barrier pressure is always higher than the seal chamber pressure by at least 1.4 bar (20 PSI).

- Plan 54 systems need careful engineering based on the application.

Recommended Application :

- Applications which require higher heat dissipation, which limits the use of Plans 53A, 53B, or 53C.

- For services where product dilution is acceptable.

- For services where media is unsuitable for flushing the inner seal faces.

- For services where Plan 53A cannot be used due to non-availability of central pressure source.

- For applications with high pressure and/ or high temperature or where an internal circulating device would not lead to effective circulation.

- Where a single system is utilized for multiple seals.