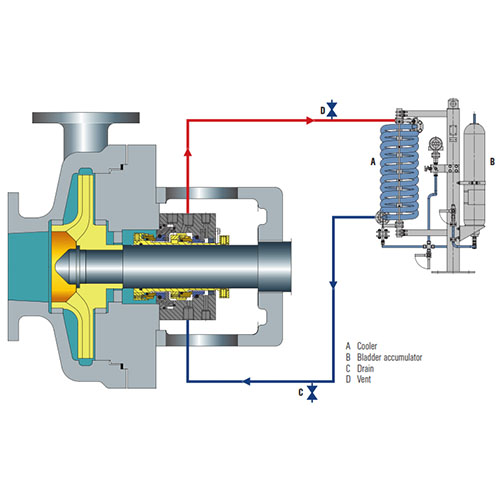

API PLAN 53B

Barrier fluid system pressurized by a bladder accumulator supplying clean liquid for an arrangement 3 pressurized dual seal.

Features

- The barrier fluid and nitrogen are separated by a bladder which effectively prevents the nitrogen from mixing with the barrier fluid as in the case of a Plan 53A.

- The pumped medium generally does not leak to the atmosphere unless the bladder pressure is lost.

- High reliability as a stand-alone system without need for a permanent nitrogen source and external pressure.

- Heat removal by water or air cooler.

- Uses an internal circulating device to ensure barrier liquid circulation.

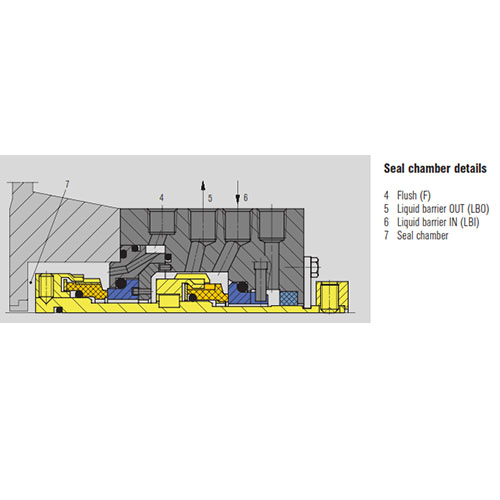

- Barrier liquid enters the process medium through the inner seal faces.

Recommended Application

Remarks, Checkpoints :

- Check with the process engineer if product contamination is acceptable.

- Check barrier fluid compatibility with the media.

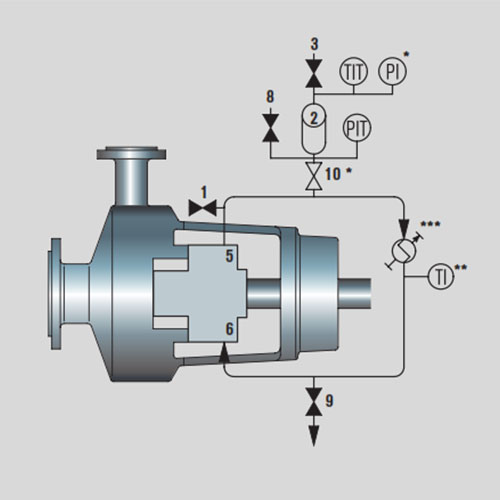

- Always pre-charge the bladder at the correct pressure to ensure the required barrier pressure at the operating temperature. Refer to the nameplate affixed to the accumulator.

- Vent the system before start-up. Later ensure that the vent line always remains closed.

- Sense the seal inlet and outlet line temperatures. Difference in the temperatures is an indication of proper flow.

- Ensure that the barrier pressure is always higher than the seal chamber pressure by at least 1.4 bar (20 PSI).

- Since there is less barrier fluid volume in the accumulator, heat dissipation is a function of the cooler efficiency.

Recommended Application :

- For services where product dilution is acceptable.

- For services where media is unsuitable for flushing the inner seal faces.

- For services where Plan 53A cannot be used due to non-availability of a permanent, reliable nitrogen supply at required pressure.

- For applications with barrier pressures above 16 bar (232 PSI) where Plan 53A cannot be used.