Our Facilities

FSD Repair center is located in Tangerang, Banten Province, Indonesia

FSD works alongside Indonesia. The repair center has 30 full time employees and totally 50 sets of manufacturing and repair devices. Besides, FSD Indonesia is the centre of Engineering which develops its own product design and engineering under the brand of FSD. The FSD brand is registered in Indonesia.

Our state-of-the-art repair facility mainly includes:

- 24” and 40” lapping machines

- Grooving software and equipment

- Automated grooving machine

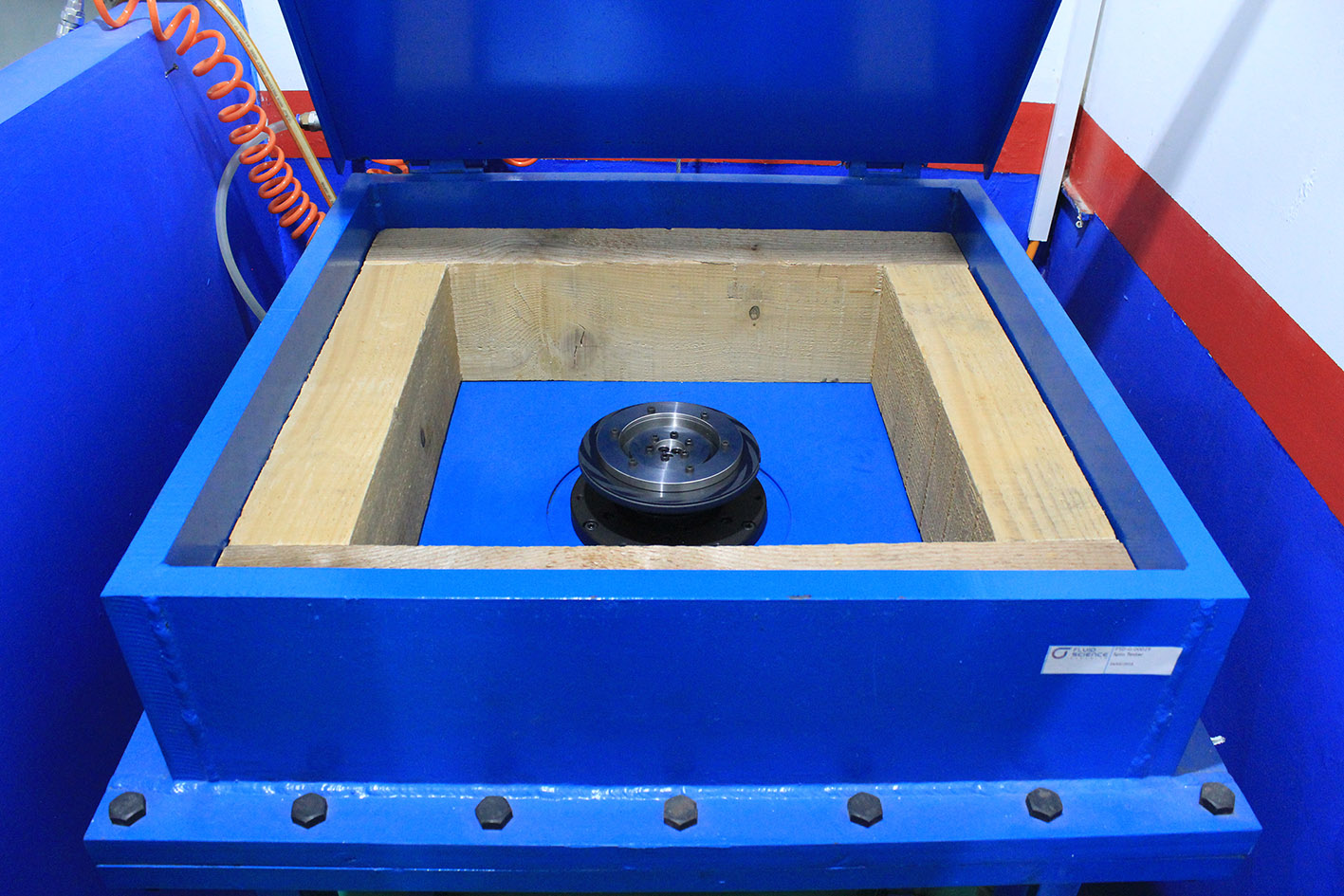

- Spin test equipment

- Balancing machine

- Dynamic test cell

- Control monitoring system

- Assembly and control room

- Lathe machine

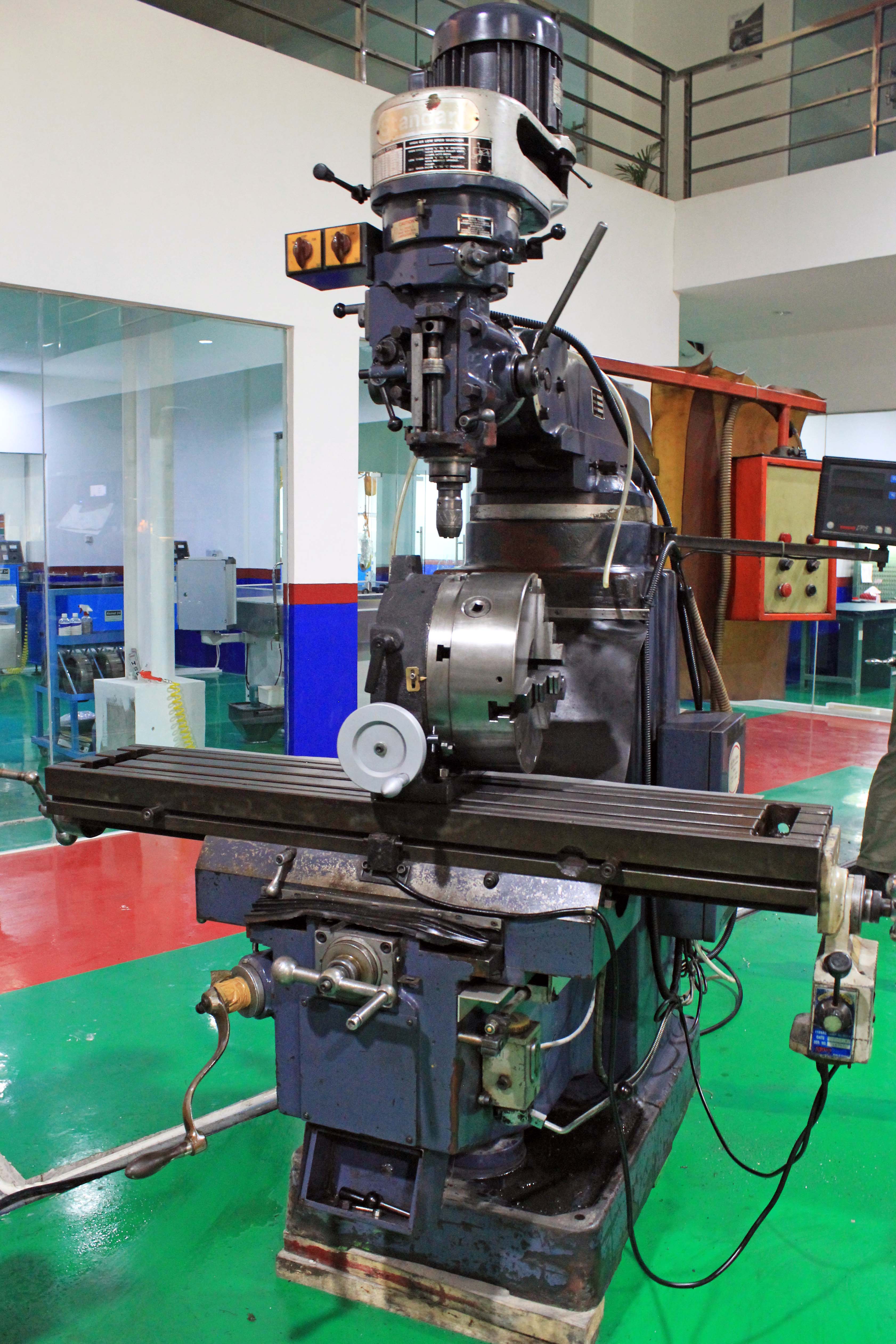

- Milling machine

- Band saw machine

- CMM and VMM

- FARO® Laser Scanner

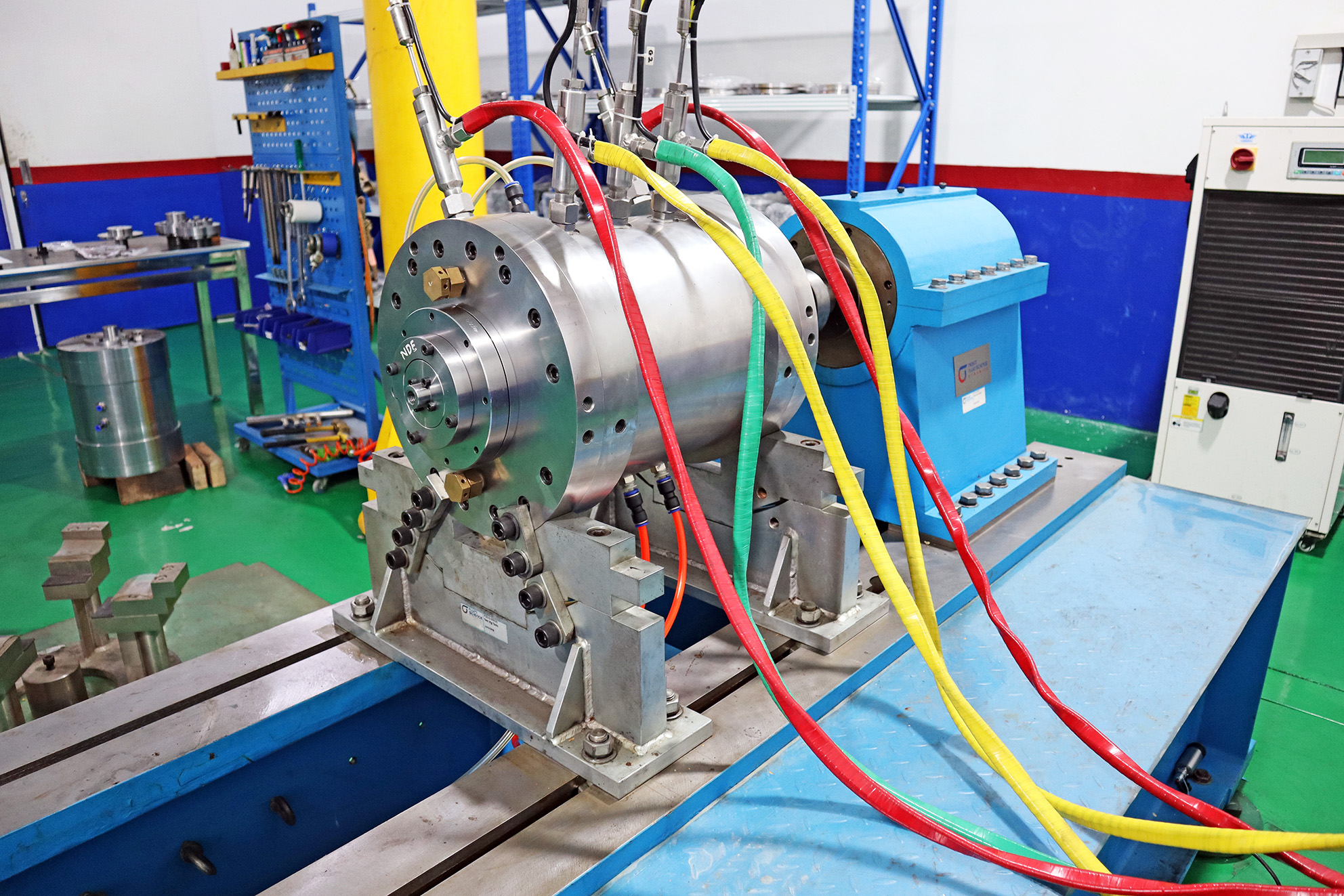

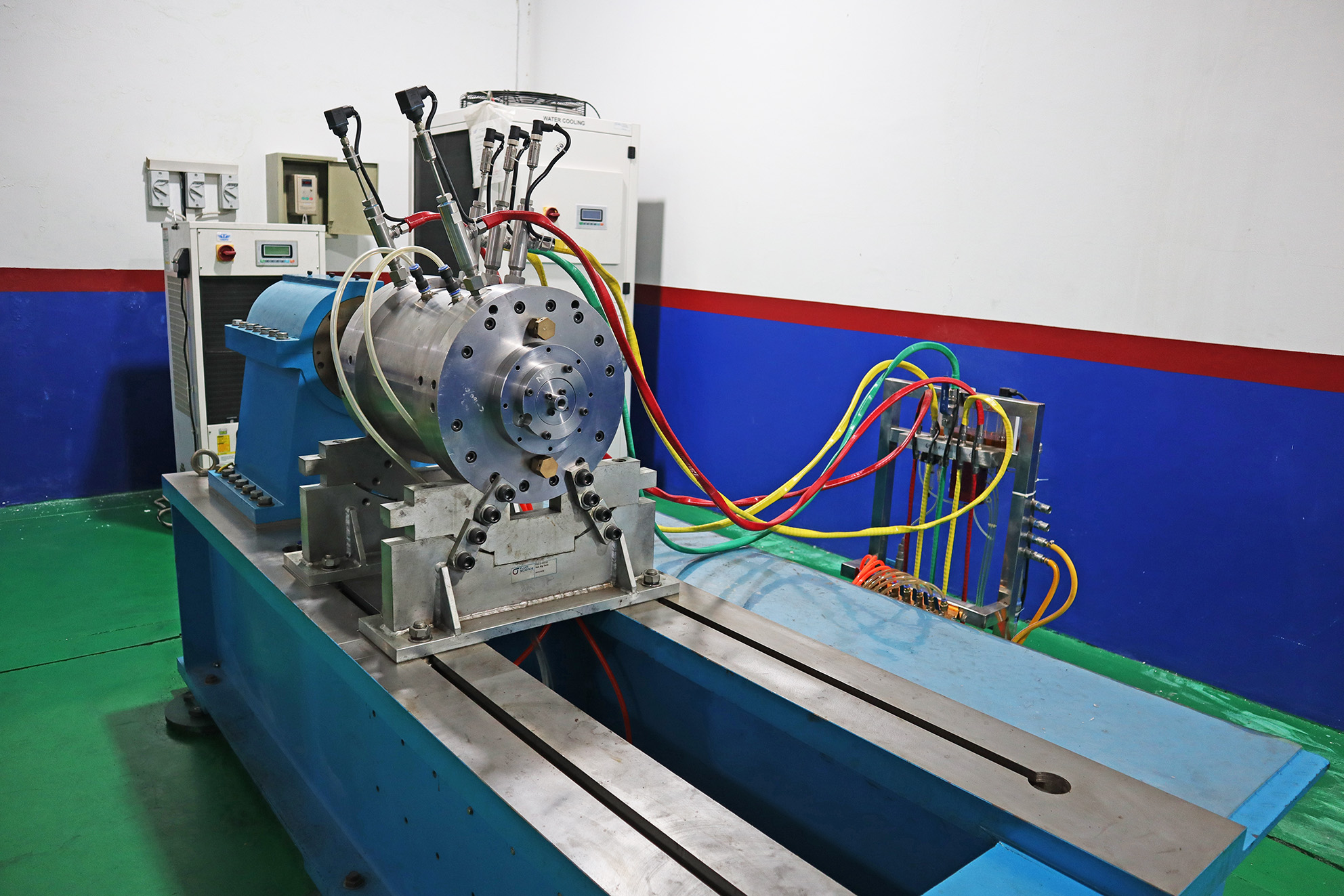

High-Pressure Dry Gas Seal Test Facility – Up to 250 barg

Our High-Pressure Dry Gas Seal (DGS) Test Facility is designed to support the most demanding compressor applications by providing reliable, real-condition performance testing at pressures up to 250 barg. This facility represents our commitment to quality assurance, operational safety, and advanced engineering capabilities.

Facility Overview

The high-pressure test facility enables comprehensive verification of Dry Gas Seal performance under simulated operating conditions. By replicating actual pressure environments, we ensure each seal meets stringent performance and safety requirements before installation in the field.

Key Capabilities

-

High-pressure Dry Gas Seal testing up to 250 barg

-

Simulation of real compressor operating conditions

-

Seal integrity and leakage performance verification

-

Functional and safety performance validation

-

Testing in accordance with customer requirements and international standards

Client Benefits

-

Increased confidence in Dry Gas Seal reliability

-

Reduced risk of failure during commissioning and operation

-

Improved compressor availability and uptime

-

Lower maintenance and lifecycle costs

-

Enhanced safety for high-pressure applications

Applications

Our High-Pressure Dry Gas Seal Test Facility supports:

-

Oil & gas production and processing

-

LNG and gas transmission systems

-

Refineries and petrochemical plants

-

High-pressure centrifugal and axial compressors

Commitment to Quality

This facility is part of our continuous investment in advanced testing infrastructure to support our clients’ critical operations. With in-house high-pressure testing capability, we deliver faster turnaround, consistent quality, and dependable results.

For more information about our High-Pressure Dry Gas Seal Test Facility or to discuss your project requirements, please contact our team.